Correo electrónico ukax janiw ch’usakïkaspati

Contraseña ukax janiw ch’usakïkaspati

Correo electrónico formato ukan pantjasitapa

Correo electrónico ukax janiw ch’usakïkaspati

Correo electrónico ukax nayratpach utjxiwa

6-20 chimpunaka(letranakampi jakhunakampikiwa)

Uka aruskipawixa janiwa chiqaparu uñjatäkiti

Correo electrónico formato ukan pantjasitapa

Correo electrónico ukax janiw ch’usakïkaspati

Correo electrónico ukax janiw utjkiti

6-20 chimpunaka(letranakampi jakhunakampikiwa)

Uka aruskipawixa janiwa chiqaparu uñjatäkiti

Yatiyawinaka

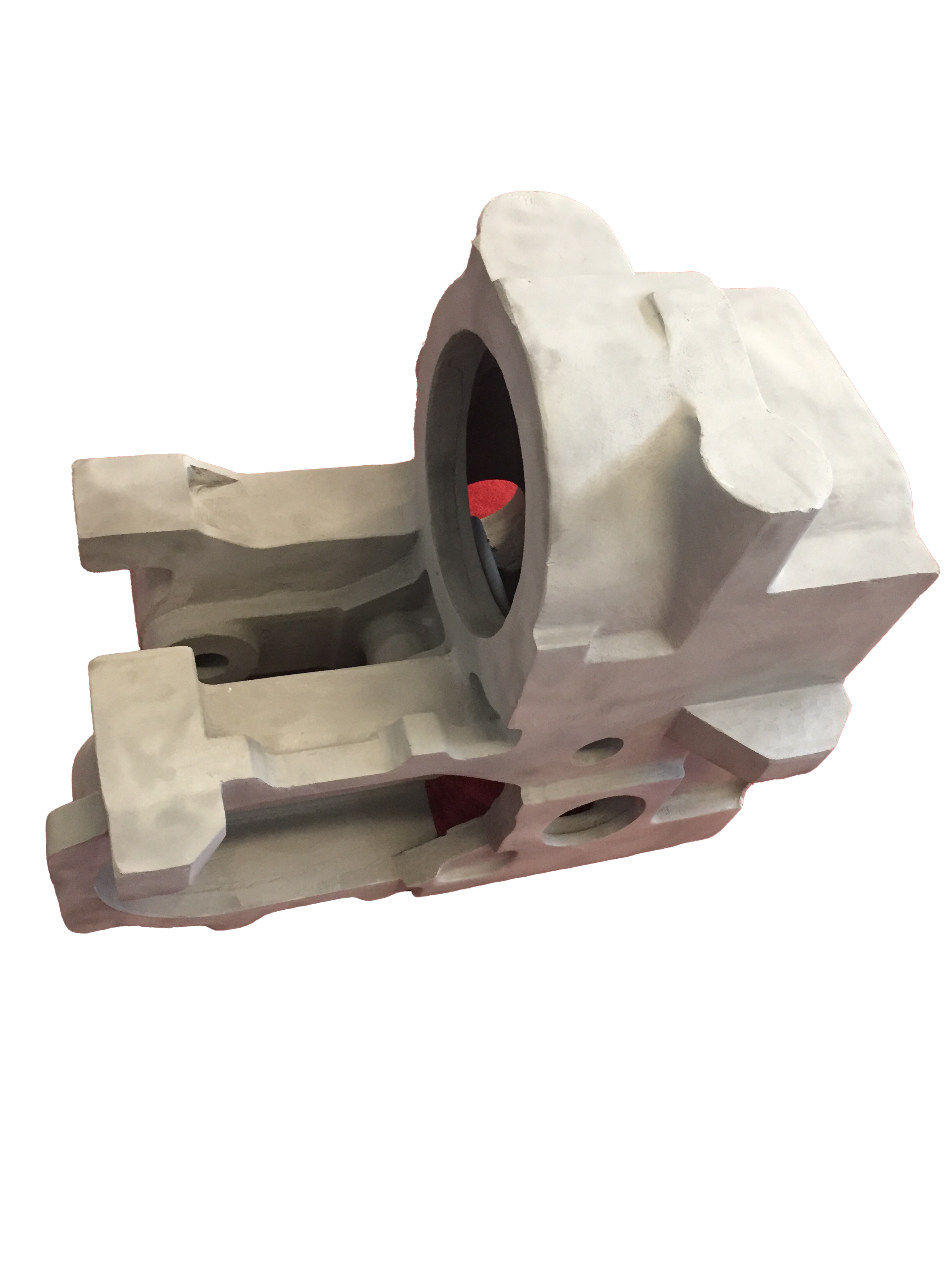

What Are the Components of CNC Lathes

Worldwide, as one of the most important factors supporting the development of the industrial industry in the world, advanced manufacturing technology has been placed at the top of the development plans of major industrial countries. As the main machine in the field of industrial machinery, CNC machine tools are widely used in aviation, automobile, equipment and other fields because of their high precision, high reliability and high efficiency. As one of the important parts of the machine tool, what are the components of the CNC lathe? You will find the answer below.

CNC lathes namely computer numerically controlled lathes, are a kind of CNC machine tools with the largest domestic use and coverage, accounting for about 25% of the total number of CNC machine tools. CNC machine tools are mechatronics products integrating machinery, electrical, hydraulic, pneumatic, microelectronics and information technologies. It is a working machine with the advantages of high precision, high efficiency, high automation and high flexibility in mechanical manufacturing equipment. The technical level of CNC machine tools and their percentages in the output and total ownership of metal cutting machine tools is one of the important indicators to measure the development of a country's national economy and the overall level of industrial manufacturing. CNC lathe is one of the main varieties of CNC machine tools. It occupies a very important position in CNC machine tools. It has been widely valued and developed rapidly by countries all over the world for decades.

CNC lathe is an automatic lathe equipped with a program control system, which can make the lathe move and process parts according to the programmed program. It integrates machinery, automation, computer, measurement, microelectronics, etc., and uses a variety of sensors. The sensors used on CNC lathes mainly include photoelectric encoders, linear gratings, proximity switches, temperature sensors, and Hall sensors. , current sensor, voltage sensor, pressure sensor, liquid level sensor, resolver, induction synchronizer, speed sensor, etc., mainly used to detect position, linear displacement, and angular displacement, speed, pressure, temperature, etc.

The CNC lathe is mainly composed of four parts:

The CNC lathe is mainly composed of four parts: the main engine part, the control part, the driving device, and the auxiliary device.

Host part

It is the main body of the CNC lathe and the mechanical part of the CNC lathe. It includes a bed, a spindle box, a tool rest, a tailstock, and a feeding mechanism.

Control part

The control part, also known as the CNC device, is the core of controlling the lathe, generally a special control computer for the lathe (including the lathe printed board circuit, the screen display, the keyboard, the paper tape, the magnetic tape, the drive circuit, etc.). The program instructions input to the control part are recorded on the information carrier and received by the program reading device or are manually input directly by the keyboard of the control part.

Drive device

The driving device is the driving part of the actuator of the CNC lathe, including the spindle motor, the feed servo motor, etc.

Auxiliary device

Auxiliary devices are some supporting components of the index control lathe, including hydraulic, pneumatic devices, cooling systems, drainage devices, protective equipment, etc.

The composition of the CNC lathe has the following structural characteristics:

A fully enclosed or semi-enclosed protective device is often used.

The CNC lathe adopts a closed protective cover to prevent chips or cutting fluid from flying out, to reduce accidental injury to the operator.

Adopt an automatic chip removal device.

The CNC lathe has a high degree of automation and less human intervention in the processing process. The inclined bed structure is often used to facilitate the use of automatic chip removal devices.

Dynamic chip removal device.

High spindle speed, safe and reliable workpiece clamping

CNC lathes often use power chucks, which are convenient and reliable to adjust the clamping force, and also reduce the labor intensity of operators.

Automatic tool change.

CNC lathes generally use automatic rotary tool holders, which can automatically replace tools during processing to achieve continuous processing of multiple processes.

The main feed drive is separated.

The main drive and feed drive of the CNC lathe use independent servo motors to make the drive chain short and reliable. At the same time, each motor can move independently or realize multi-axis linkage as required.

Conclusion

For more information about cnc machining precision, short run cnc machining,cnc machining engineering, we are glad to answer for you.