Correo electrónico ukax janiw ch’usakïkaspati

Contraseña ukax janiw ch’usakïkaspati

Correo electrónico formato ukan pantjasitapa

Correo electrónico ukax janiw ch’usakïkaspati

Correo electrónico ukax nayratpach utjxiwa

6-20 chimpunaka(letranakampi jakhunakampikiwa)

Uka aruskipawixa janiwa chiqaparu uñjatäkiti

Correo electrónico formato ukan pantjasitapa

Correo electrónico ukax janiw ch’usakïkaspati

Correo electrónico ukax janiw utjkiti

6-20 chimpunaka(letranakampi jakhunakampikiwa)

Uka aruskipawixa janiwa chiqaparu uñjatäkiti

Yatiyawinaka

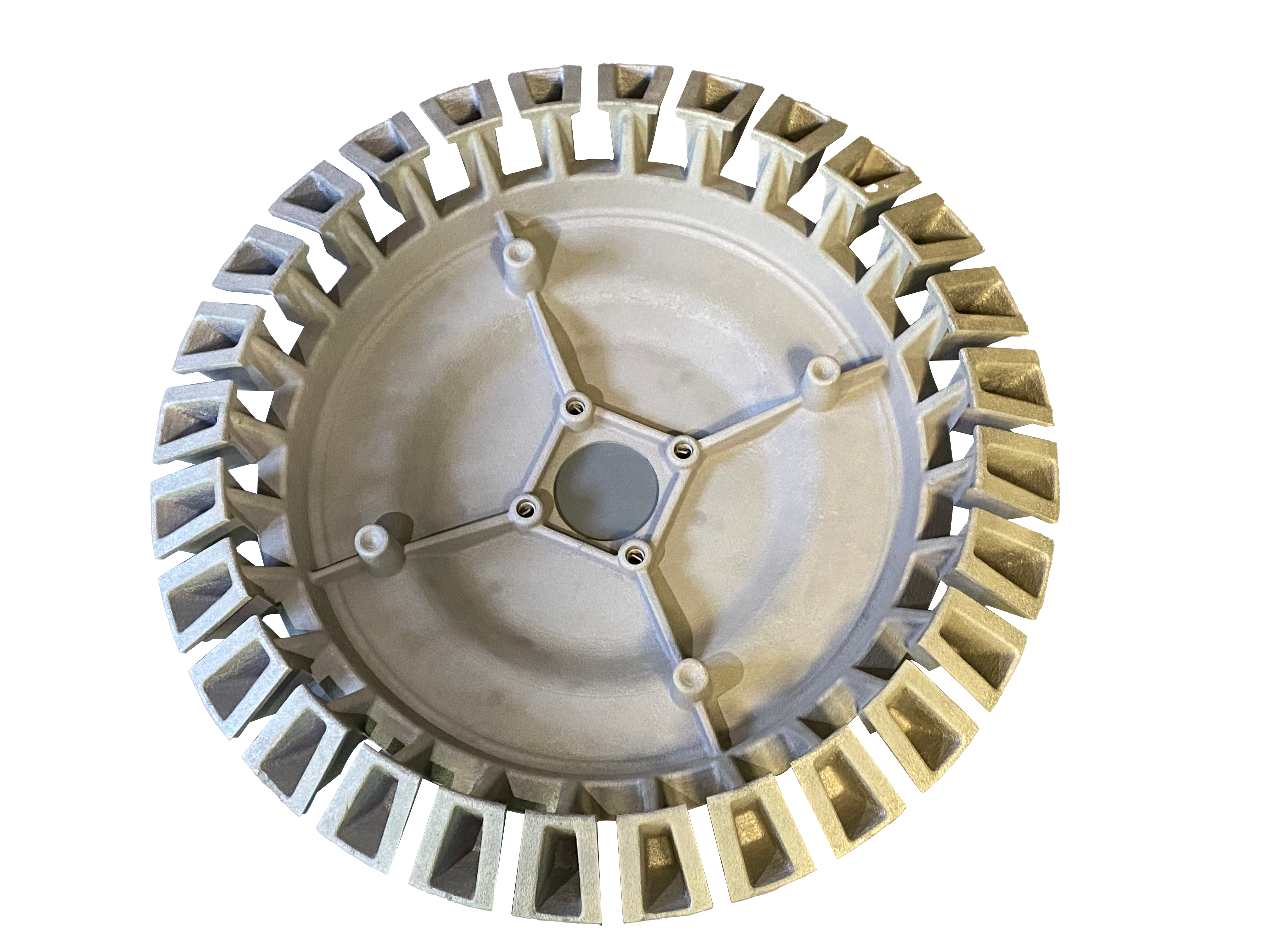

What are the Advantages of Sand Casting?

Sand casting is a kind of casting technology. The mold used in sand casting is generally composed of outer sand mold and core. Because the molding materials used in sand casting are cheap and easy to obtain, and mold manufacturing is simple, it can adapt to the single-piece production, batch production, and mass production of castings. For a long time, it has been the basic process in casting production. At present, internationally, in the production of all castings, 60-70% of castings are produced by sand mold, and about 70% of them are produced by clay sand mold.

Sand casting crusher wear-resistant parts are still very common in China, such as jaw plate, high chromium plate hammer, broken wall, rolling mortar wall, etc., because in crusher equipment, as a relatively large wear-resistant casting, the accuracy is not very high, especially for jaw plate, the finished products are hardly polished by lathe, and the broken wall, rolling mortar wall, roller skin and so on are only parts of the casting that need to be polished by lathe, so it is particularly suitable for sand casting, Because the wear-resistant parts of sand casting jaw plate, high chromium plate hammer, broken wall, rolling mortar wall, roller skin and so on are more durable than other products such as EPC process by more than 20%. However, EPC has the advantages of high dimensional accuracy, small machining allowance, convenient dry sand and sand falling, more than 50% reduction of cleaning and grinding workload, and labor cost savings. Therefore, the price of EPC is relatively low.

Sand casting is a kind of casting technology. The mold used in sand casting is generally composed of outer sand mold and core. Because the molding materials used in sand casting are cheap and easy to obtain, and mold manufacturing is simple, it can adapt to the single-piece production, batch production, and mass production of castings. For a long time, it has been the basic process in casting production. At present, internationally, in the production of all castings, 60-70% of castings are produced by sand mold, and about 70% of them are produced by clay sand mold.

Sand casting crusher wear-resistant parts are still very common in China, such as jaw plate, high chromium plate hammer, broken wall, rolling mortar wall, etc., because in crusher equipment, as a relatively large wear-resistant casting, the accuracy is not very high, especially for jaw plate, the finished products are hardly polished by lathe, and the broken wall, rolling mortar wall, roller skin and so on are only parts of the casting that need to be polished by lathe, so it is particularly suitable for sand casting, Because the wear-resistant parts of sand casting jaw plate, high chromium plate hammer, broken wall, rolling mortar wall, roller skin and so on are more durable than other products such as EPC process by more than 20%. However, EPC has the advantages of high dimensional accuracy, small machining allowance, convenient dry sand and sand falling, more than 50% reduction of cleaning and grinding workload, and labor cost savings. Therefore, the price of EPC is relatively low.

Searching for sand casting components, sand casting copper, gravity sand casting supplier, wholesaler, manufacturer from China, you can get high-quality products at a nice price.