Correo electrónico ukax janiw ch’usakïkaspati

Contraseña ukax janiw ch’usakïkaspati

Correo electrónico formato ukan pantjasitapa

Correo electrónico ukax janiw ch’usakïkaspati

Correo electrónico ukax nayratpach utjxiwa

6-20 chimpunaka(letranakampi jakhunakampikiwa)

Uka aruskipawixa janiwa chiqaparu uñjatäkiti

Correo electrónico formato ukan pantjasitapa

Correo electrónico ukax janiw ch’usakïkaspati

Correo electrónico ukax janiw utjkiti

6-20 chimpunaka(letranakampi jakhunakampikiwa)

Uka aruskipawixa janiwa chiqaparu uñjatäkiti

Yatiyawinaka

How Is the Machining Center Model Divided

Machining center is processing-type mechanical equipment gradually produced due to changes in production demand in recent years. It is developed from the CNC milling machine, and the difference from the CNC milling machine is that it has a tool magazine. Many manufacturers who come into contact with machining center equipment for the first time do not understand what models of machining centers are available, how the models are divided, and what type of machining centers meet their own production needs. Next, the editor will give you a detailed introduction to the models of the machining center and how to divide the models.

We know that machining centers are divided into vertical machining centers, horizontal machining centers, and gantry machining centers according to their routes. According to the type of guide rail, it can be divided into wire gauge and hard rail. VMC is the most common type of machining center, and it is also the most used machining center on the market today—vertical wire gauge machining center. XH is a vertical hard rail machining center. XK is a CNC milling machine.

How is the machining center model divided?

Taking the vertical wire gauge machining center as an example, what do VMC650, VMC850, and vmc1060 mean?

In fact, 650, 850, and 1060 refer to the stroke of the machining center, especially the processing stroke of the X-axis. This determines how large a workpiece can be processed by the machining center.

- The stroke of the vmc650 machining center is 650*500*500 mm;

- The stroke of VMC850 machining center is 800*500*500 mm;

- The stroke of VMC1060 machining center is 1060*600*600 mm;

More than 1060 strokes are usually called large machining centers, 650 or less strokes are small machining centers, and 850 is the most common stroke size, so it is widely used.

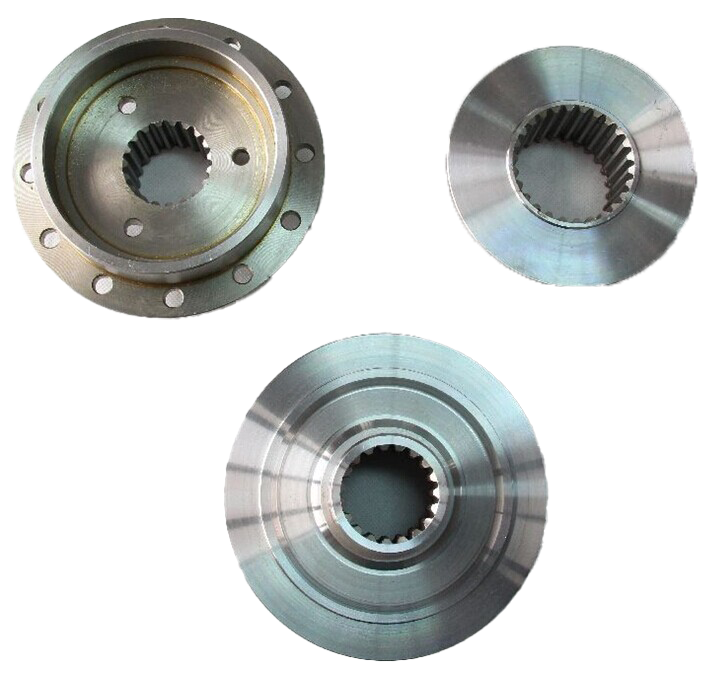

The machining center can clamp all kinds of mold workpieces within its processing range at one time, and complete various processes such as drilling, milling, boring, expanding, reaming, and tapping. Generally speaking, if there are no special requirements and the actual processing range allows, the X-axis of the machining center is generally chosen to be smaller for price, cost and budget considerations.

In addition, there is another component that affects the model of the machining center, and that is the table. If the size of the workpiece to be processed is relatively large, but the size to be processed is not large, then you need to consider the placement and clamping issues, then you must pay attention to the size of the worktable of the machining center and whether the space can hold your workpiece. The places often referred to by the workbench are: the area of the workbench, the distance from the end face of the main shaft to the workbench, and the maximum bearing capacity of the workbench.

Conclusion

All in all, when purchasing a machining center, you must understand your machining needs and determine the commonly used machining dimensions before you can choose the appropriate model.

For more information about 3 axis cnc mill,cnc milling aluminum,cnc pipe bending, we are glad to answer for you.